An outdated noticed usually uttered by {an electrical} engineer (or their hapless techs) when an digital system releases its magic smoke goes one thing like this: “The transistor bravely sacrificed itself to guard the fuse.”

This can be a succinct method of claiming that typical fuses (and most sorts of circuit breakers) shouldn’t be counted on to guard a downstream load from full destruction within the occasion of a fault, however solely to (hopefully!) forestall a hearth from overheated wiring, sparking, and so on.

This regrettable shortcoming is generally as a consequence of physics and economics: a traditional fuse or thermal circuit breaker will take about 1,000 to 10,000 instances too lengthy to guard most semiconductor gadgets from overcurrent even when the latter are grossly over-sized (i.e. price far more than is economically justifiable). Specialised circuit breakers that mix a fast-acting magnetic journey together with the standard thermal one can permit for much less over-sizing of the downstream semiconductors, however they themselves are rather more costly gadgets, so as soon as once more this appears economically questionable.

To actually defend the downstream semiconductor gadgets from short-circuit faults with out affected by nuisance tripping throughout regular working circumstances requires an overcurrent protecting system that responds to extreme overcurrents in 1 to 10 microseconds whereas nonetheless sustaining a extra typical fuse response to average overcurrents, which is exactly what an digital fuse can do—and probably at a aggressive price to the specialised magnetic-thermal circuit breaker, particularly if it permits the usage of extra rationally-rated semiconductors.

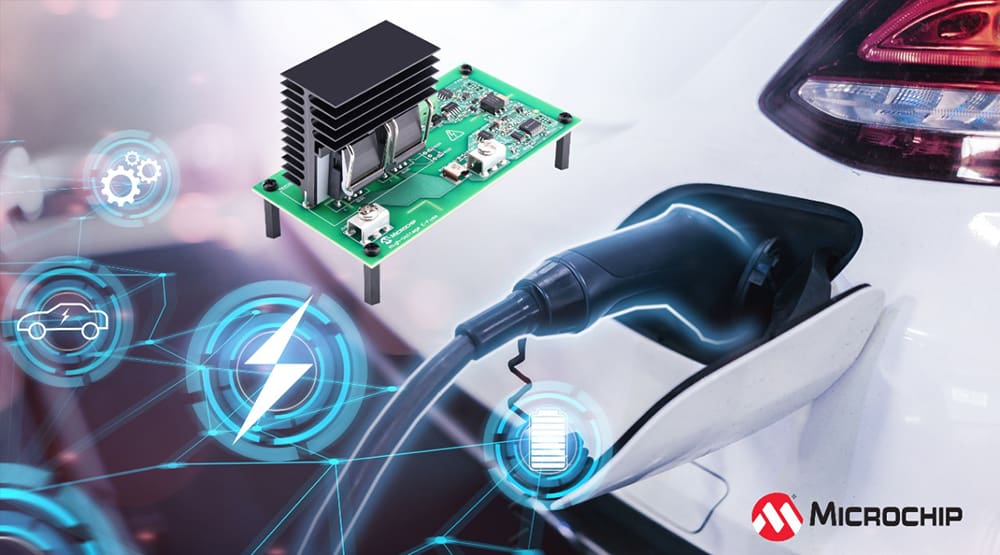

Microchip’s Silicon Carbide E-Fuse demonstrator is offered in six variants for 400–800 V battery methods.

To higher perceive the professionals and cons of digital fuses, a overview of typical fuse and circuit breaker expertise is so as. All fuses basically depend on the melting of a fusible factor to interrupt the circuit throughout overcurrent circumstances. The period of time required is inversely proportional to the diploma of overcurrent. Because the heating of the fusible factor is the results of I2R losses, a doubling of present ought to lead to a quartering of the time to blow (that’s, following a sq. legislation). Certainly, fuses are most frequently characterised by I2t curves as a shorthand method of expressing the power required to rupture the fusible factor by leaving out the resistance, R, within the power equation of I2R over a given time, t.

E-fuses can’t solely reply far quicker to an overcurrent fault, they’ll additionally implement present vs time behaviors that may be impractical (or inconceivable) with typical applied sciences.

Varied tips can be utilized to change this present vs time habits—significantly in lengthening the time that average overcurrents might be tolerated with out unduly compromising the response to shorts—however at greater overcurrents the period of time required for a fuse to open tends to an asymptotic minimal (as a result of want for the molten metallic to truly fall far sufficient away to interrupt the circuit).

Moreover, if the fuse should break a DC circuit above 50 V or so, an arc will probably be developed because the fusible hyperlink melts, prolonging the period of time that present will probably be allowed by means of it (albeit with a voltage drop throughout mentioned arc). This arcing drawback turns into more and more tough to handle with open-circuit DC voltage (it’s much less of a difficulty for AC, due to the periodic returning to 0 V), to the purpose that some type of compelled arc quenching is required above 300 VDC or so (by surrounding the fusible factor with quartz sand, or spring loading it, and so on).

Thermal circuit breakers additionally depend on I2R heating to journey, however this happens by way of the heating of a bimetallic strip that causes it to bend. Cheap thermal circuit breakers that aren’t anticipated to journey various instances of their operational life will make the most of the bimetallic strip straight to maneuver the current-carrying contacts aside (by way of self-heating of the strip from load present), however extra sturdy designs—and particularly at greater currents—will use a separate heater coil across the strip which is able to itself actuate a toggling mechanism so that there’s a snap-action response upon reaching the crucial journey temperature, somewhat than a extra gradual motion which might encourage arcing. The toggle mechanism permits for both a bistable motion, which means it’s steady in both the closed or open (tripped) positions, or a monostable motion, which means it should robotically return to the closed place after the bimetallic strip has cooled down.

Whatever the particular design of a thermal circuit breaker, it should endure from some downsides that don’t afflict the easier fuse (or to not the identical diploma, anyway). For one factor, it should take far longer to reply to a extreme overload or short-circuit than a fuse of the identical nominal present score. For an additional, the journey present (or the time delay earlier than tripping happens) will probably be extra delicate to the ambient temperature, as a result of the temperature rise wanted to function the bimetallic strip should essentially be restricted in order to not create the very fireplace hazard it’s supposed to forestall.

Thermal-magnetic circuit breakers handle the extreme delay in responding to extreme overloads that’s attribute of purely thermal circuit breakers by passing the load present by means of a solenoid—that’s, a linear coil of wire round a shifting ferromagnetic plunger—which might independently function the toggling mechanism.

The magnetic pressure developed by a solenoid is proportional to the present flowing by means of it, so the upper the load present, the extra forcefully (and due to this fact quicker) its plunger will transfer. The magnetic-hydraulic circuit breaker addresses the sensitivity of journey present to ambient temperature by changing the bimetallic strip with a viscous fluid that the solenoid plunger should function in opposition to. This preserves the comparatively gradual response to average overloads typical of the thermal circuit breaker with the quicker response to short-circuits achieved by the magnetically-actuated mechanism.

The aforementioned shortcomings of typical fuse and circuit breaker designs might be addressed by going with an digital resolution—that’s, by utilizing a semiconductor swap to interrupt the circuit within the occasion of a fault situation—giving rise to what’s popularly known as an digital fuse, or e-fuse for brief (although it could be extra correct to explain it as an digital circuit breaker). E-fuses can’t solely reply far quicker to an overcurrent fault, they’ll additionally implement present vs time behaviors that may be impractical (or inconceivable) with typical applied sciences, in addition to defend in opposition to extra hazards similar to overvoltage, over- and under-temperature, and so on, at little to no further price (i.e. with a couple of extra elements or extra strains of code). Moreover, e-fuses might price lower than typical electromechanical circuit breakers of comparable present interrupt score (although, admittedly, they examine much less favorably to standard fuses on this regard).

The best implementation of an e-fuse is a current-measuring circuit feeding a comparator that controls a semiconductor swap. At working voltages as much as about 50 V and most currents as much as about 20 A, the present measuring circuit will sometimes be a resistive shunt that’s wired in sequence with the damaging line (aka the low facet), whose voltage drop is multiplied by an op-amp-based differential amplifier with a modest quantity of acquire (2x to 10x is typical right here) in order to not incur too excessive of an influence loss within the shunt. At greater voltages and/or currents, a present measuring circuit based mostly on a Corridor impact present sensor (or a competing expertise, similar to big magnetoresistance) will probably be extra engaging, as a result of there isn’t a I2R loss as incurred by a shunt, and galvanic isolation is robotically offered. Both method, the output of the current-measuring circuit will probably be in comparison with a reference voltage by a comparator, which itself might be applied with an analog IC (such because the venerable LM331 from Texas Devices), although it’s in all probability extra widespread to make use of a microcontroller IC as of late, particularly if different protecting features are to be applied. A key requirement for the comparator operate is that it have hysteresis, or barely completely different turn-on and turn-off thresholds, to forestall oscillation when the load present is close to the overcurrent journey level.

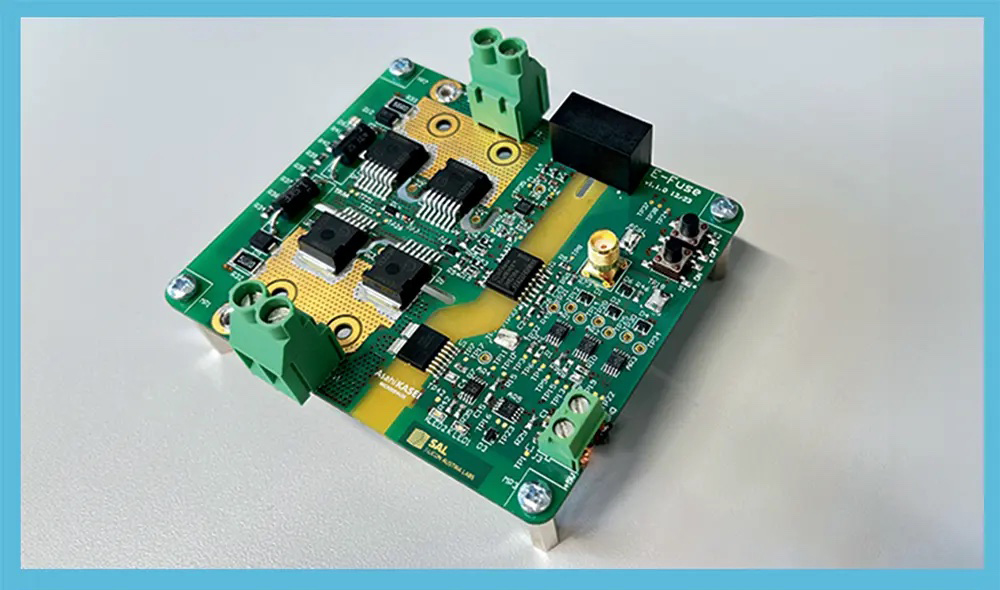

An e-fuse proof of idea for prime voltage 800 V automotive purposes developed by Asahi Kasei Microdevices Company and Silicon Austria Labs GmbH.

The output of the comparator will possible be unable to straight drive the semiconductor swap, so some type of gate driver circuit or IC will probably be required, however this might merely be a complementary pair of bipolar transistors wired within the traditional push-pull configuration. The semiconductor swap is mostly both a single low-side MOSFET (for blocking present stream in a single path—i.e. solely discharge, from the attitude of a battery), or two MOSFETs wired source-to-source (for bidirectional blocking). This latter configuration is usually used within the BMS for Li-ion batteries (which, in any case, incorporates the entire features of an e-fuse, along with its cell monitoring and balancing duties).

A much less apparent requirement for the semiconductor swap is that the impedance of the upstream energy supply not be so low as to make it inconceivable for the e-fuse’s swap to outlive a tough quick downstream.

At greater voltages, it’s extra regular to place the swap within the excessive facet (i.e. the constructive line) and use both an remoted or level-shifting gate driver to regulate it, particularly when the damaging line have to be earth grounded for security causes. One key requirement for the semiconductor swap is that it should be capable of stand up to a better peak present (or, extra appropriately, have a better fusing power—I2t once more) than the system it’s defending; a much less apparent requirement is that the impedance of the upstream energy supply not be so low as to make it inconceivable for the e-fuse’s swap to outlive a tough quick downstream.

Observe that this latter requirement additionally applies to standard circuit breakers and fuses, however is way simpler to satisfy with gadgets that don’t depend on lively semiconductors. This means that the swap(es) within the e-fuse will probably be beefier, and due to this fact dearer, than the semiconductor gadgets it’s supposed to guard, which might be economically questionable if not for the e-fuse’s prolonged safety capabilities and far quicker response pace.

Lastly, e-fuses clearly require energy to function, and if the voltage of the upstream power supply isn’t straight usable by the e-fuse circuitry (within the vary of three V to 30 V, say) then some kind of DC-DC converter can even be wanted, including to the general price whereas reducing reliability. This additionally signifies that an e-fuse can’t straight substitute an current typical fuse or circuit breaker, because it wants one other wire again to the ability supply to finish its provide circuit (although that is sometimes straightforward to retrofit).

It is very important word that there are some energy circuit topologies during which no exterior fuse will be capable of defend its semiconductor gadgets from failure, no matter fuse expertise or how briskly it will probably open. The most typical instance of such are the switches in a 3-phase inverter, as they’re instantly preceded by a capacitor wired straight throughout the provision rails. This capacitor basically presents a really low-impedance voltage supply to the switches, which implies it should ship a really excessive peak present to them within the occasion of a fault similar to overlapping conduction of each switches in a bridge leg or a turn-to-turn quick within the windings of the motor.

The one good resolution for shielding the switches that are straight fed by a voltage supply is lively current-limiting on the particular person swap stage (aka pulse-by-pulse present limiting). One other scenario during which an e-fuse would possibly fare poorly—particularly compared to its typical counterparts—is when subjected to a extreme voltage spike, similar to from a close-by oblique lightning strike. That is primarily as a result of passive electrical (fuses) or electromechanical (circuit breakers) gadgets are typically way more rugged than their digital counterparts (e-fuses). In conclusion, e-fuses aren’t a panacea, they usually received’t prevent from unhealthy design choices and part decisions within the energy circuits they’re supposed to guard, however they might scale back general guarantee and technical assist prices, whereas probably costing much less up entrance, in order that they’re positively value contemplating.

This text first appeared in Situation 69: July-September 2024 – Subscribe now.